Meet the improved propeller test bench

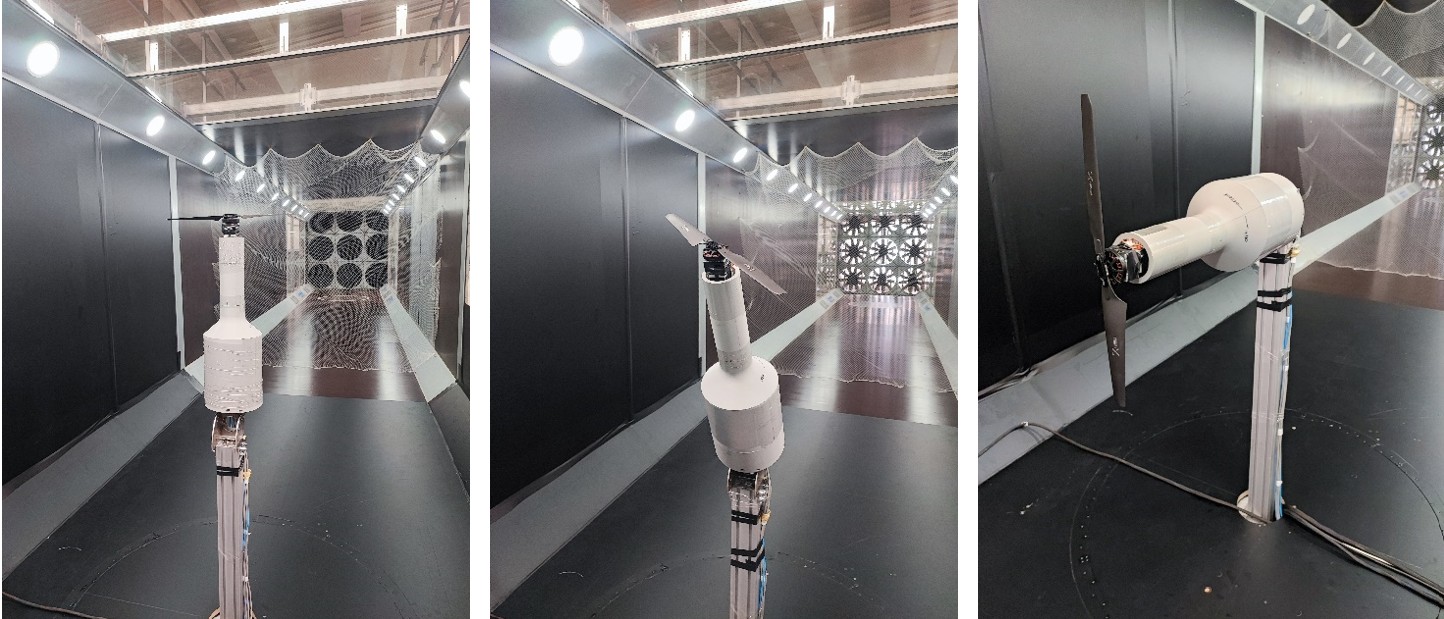

The first workpackage of ENOLA is focused on propeller modelling, testing an optimization. A crucial tool for the success of these tasks is accurate experimental validation, which is performed in our wind tunnel at UPV through a custom-built propeller test bench. In this update, you can find more information on this facility.

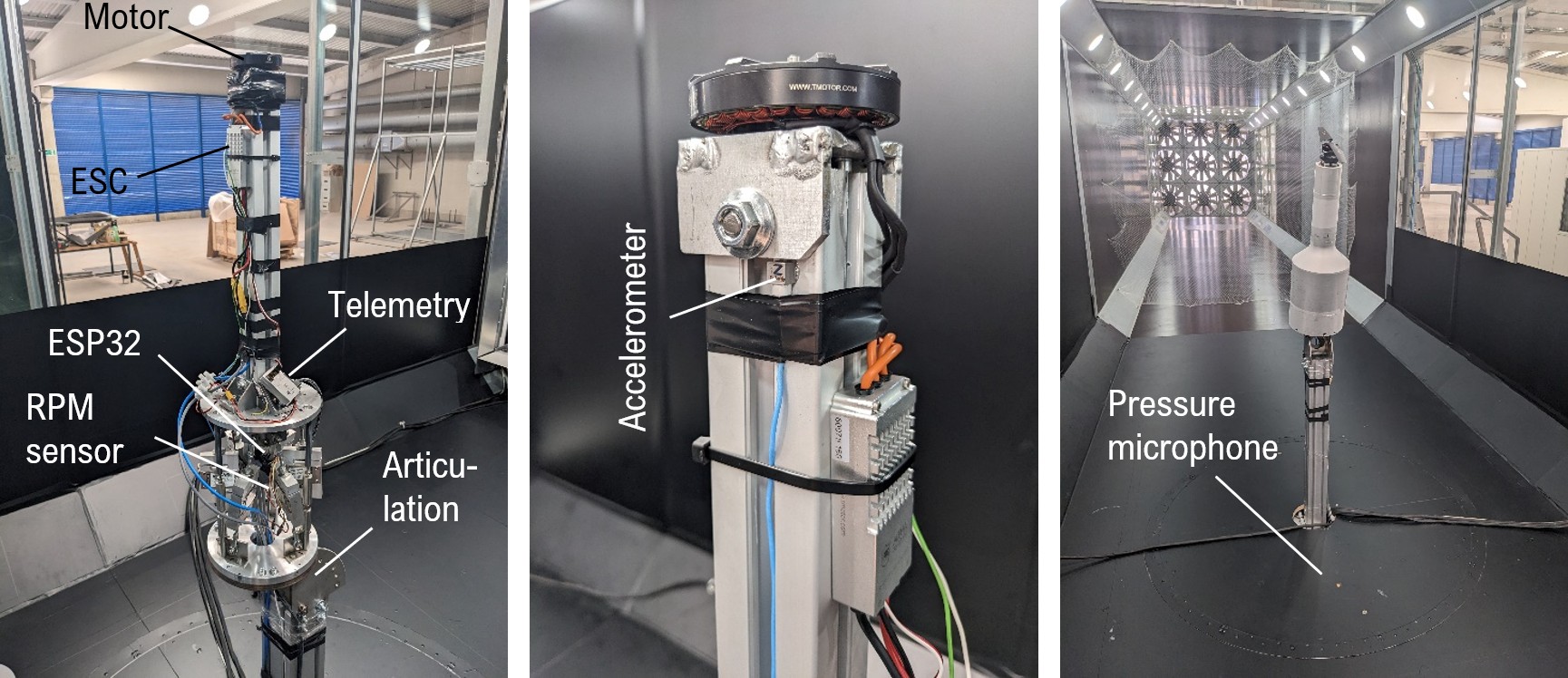

Aerodynamic forces and moments created by the propeller at different advance ratios and flow angles are measured through a custom balance, which is fixed directly to the concrete floor the facility with extruded aluminium profiles. Readings from the load cells of the balance are directly acquired through a National Instruments DAQ system. To this custom bal-ance, the motor and propellers were affixed through an extruded aluminium profile, which was then covered by a custom 3D printed fairing. In turn, the balance was affixed to a support beam through an articulation, which allowed repositioning the propeller at the required angles with respect to the wind direction.

In order to avoid interference of the balance and supports as much as possible, the motor and propeller were mounted on top of an aluminium profile. This profile also allowed mounting of the engine Electronic Speed Controller and telemetry module, as well as a miniaturized triaxial accelerometer. The telemetry module stored different operation variables during each test, although redundant measurements were taken through an electronic speed sensor. This speed sensor was connected to a microcontroller, which was also connected to the ESC and thus provided throttle command to the motor.

The microcontroller was connected through USB to a microcomputer, which was in turn connected to the private instrumentation ethernet network of the wind tunnel. To this network a National Instruments CompactDAQ system was also connected, featuring two IEPE data acquisition modules. These were used to record the acceleration data coming from the triaxial accelerometer and also noise data from a pressure microphone mounted flush to the wind tunnel floor.

Since the motor and ESC advertised a regenerative braking feature, a bidirectional power supply was selected to power the setup, in order to avoid back-current damage to the power supply or the ESC. This power supply was also linked to the wind tunnel private ethernet network to facilitate additional voltage, current and power readings.